Technology-Translicent Stone

Biggest size:1mm(1600*3200mm)2.8kg/㎡ 3mm(2000*3200mm)7.5kg/㎡ 5mm(2000*3200mm)12kg/㎡

Applications

Can be used indoors and outdoors where there is light source, such as bars, hotel background walls, bar counters, light boxes, wall lamps, lighting, luminous furniture, and island counters.

Translicent Stone

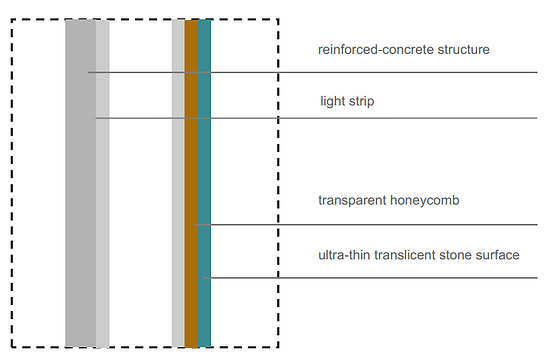

Natural stone surface+transparent honeycomb+light guide plate+light strip

Construction Conditions

-

The construction surface should be clean, flat, dry and solid.

-

Measure the construction surface;

-

Cut translicent stone into the specifications as required;

-

Use sandpaper to smooth the edges;

-

Apply glue on the back of the product (full glue or spot coating);

-

Paste the translucent product to the translucent material (transparent honeycomb, acrylic, glass);

-

When pasting, the translicent stone should be 10-15mm away from the light source;

-

After the glue is dry, remove the tape and cut a groove on the back of the product.

Technology Translicent Stone:

Wall Pasting Method

Ultra-thin stone

Construction technique diagram

1

2

3

4

5

6

7

8

Based on the construction drawings and processing orders, familiarize oneself with the size and method of each part, and figure out the relationship between the holes, corners and other parts; Check whether the horizontal and vertical flatness of the base layer meets the installation requirements, and clear the debris on the base layer surface

Before formal assembly, the ultra-thin marble panels in each area should be rechecked for their patterns, colors, and textures according to their numbers.

In order to check and control the position of ultra-thin marble slabs, snap the finished surface line according to the construction drawings.

Layout the ultra-thin marble slabs in two mutually perpendicular directions in the room, combining the construction drawings and the actual dimensions of the room, so as to check the gaps between the slabs and check the slabs and the walls, columns, openings, etc. relative position.

Wipe dry or let the surface dry before laying

According to the numbers and patterns during the trial assembly, layout ultra-thin marble one row vertically and horizontally to serve as benchmarks for large-area paving.

Apply neutral silicone structural adhesive: Clean the back of the ultra-thin marble slab first, apply neutral silicone structural adhesive around the back of the slab, and then apply cross adhesive in the middle. Also can apply appropriate marble adhesive for temporary fixation.

When placing, the four corners of the stone should fall down at the same time. Use a rubber hammer or wooden hammer to lightly tap the wooden backing board. Level it with an iron level according to the horizontal line. After laying the first piece, lay it sequentially to both sides and in the backward direction. The panels and corners, edges and walls should be tightly integrated without any gaps.